Panablok panels and their use in the steel fame Structural Envelope Building System have been independently tested and accredited by the Building Research Establishment (BRE) and all additional structural performance characteristics have been independently calculated and verified by structural engineers.

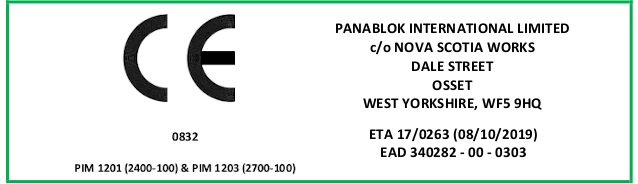

Panablok International Limited has been accredited by the BRE in accordance with European Assessment Document (EAD) 340282-00-03A which covers the whole of the EU (the associated Declaration of Performance can be viewed in the PDF below). Panablok International Limited has also attained ISO 9001:2015 (Quality Control) certification and additionally, all components used in the manufacture of Panablok panels are sourced from parties that are ISO 9001 certified.

Dimensions

Width: 1200mm

Lengths: 2400mm (78kg), 2700mm (87.75kg)

Overall Thickness: 100mm

Average Panel Weight: 27kg/m2

Lengths: 2400mm (78kg), 2700mm (87.75kg)

Overall Thickness: 100mm

Average Panel Weight: 27kg/m2

Thermal Conductivity

PU Core Conductivity 0.023w/mk

Fire Performance

Loaded Fire Resistance Test (to 6 Storey Equivalent)

Panel + double layer of 15mm FireLine board

EN 1365-1:2012 80kN (80kN equating to 23.3kN/m) Load

Load Bearing Capacity:

Result: 75mins - No failure

Integrity (Sustained Flaming/Gap Gauge/Cotton Pad)

Result: 75mins - No failure

Insulation

Result: 75mins - No failure

EN 1365-1:2012 80kN (80kN equating to 23.3kN/m) Load

Load Bearing Capacity:

Result: 75mins - No failure

Integrity (Sustained Flaming/Gap Gauge/Cotton Pad)

Result: 75mins - No failure

Insulation

Result: 75mins - No failure

Acoustic Characteristics

Acoustic measurements:

Measurements of airborne and sound insulation BS EN10140-2:2010 to BS EN ISO 10140-1:2010+A2:2014

Fire Testing Regime:

Loaded Fire Resistance Test to EN 1365-1:2012 80kN Load (23.3KN/m)

Internal Walls (Acoustic & Fire):

Airborne Sound Insulation: Acoustic Value - 40dB

Fire Resistance: 75mins

Separating (Party) Walls (Acoustic & Fire):

Airborne Sound Insulation: Acoustic value - 52dB

Fire Resistance: 75mins (One side)

External Walls (Acoustic & Fire):

Airborne Sound Insulation: Acoustic Value - 40dB

(Panel & Linings)

+ Brickwork outer-leaf & 50mm Cavity - 54dB

Fire Resistance: 75mins

Measurements of airborne and sound insulation BS EN10140-2:2010 to BS EN ISO 10140-1:2010+A2:2014

Fire Testing Regime:

Loaded Fire Resistance Test to EN 1365-1:2012 80kN Load (23.3KN/m)

Internal Walls (Acoustic & Fire):

Airborne Sound Insulation: Acoustic Value - 40dB

Fire Resistance: 75mins

Separating (Party) Walls (Acoustic & Fire):

Airborne Sound Insulation: Acoustic value - 52dB

Fire Resistance: 75mins (One side)

External Walls (Acoustic & Fire):

Airborne Sound Insulation: Acoustic Value - 40dB

(Panel & Linings)

+ Brickwork outer-leaf & 50mm Cavity - 54dB

Fire Resistance: 75mins

Durability

Assumed Working Life

Load-Bearing Structure/Non-Accessible Materials & Components - 50 years

Repairable Materials & Components - 25 years

Hard Impact: BS EN 596 Adequate Resistance

Soft Impact: BS 8200 Adequate Resistance

9mm MgO facing boards conform to “Severe Duty” applications under BS 5234-2

Load-Bearing Structure/Non-Accessible Materials & Components - 50 years

Repairable Materials & Components - 25 years

Hard Impact: BS EN 596 Adequate Resistance

Soft Impact: BS 8200 Adequate Resistance

9mm MgO facing boards conform to “Severe Duty” applications under BS 5234-2

Facings

9mm & 12mm MgO Render Board

U-Value

Panablok 100mm Panel - 0.25w/m²k

Indicative Fire Performance Evaluation Developed for SIP Panels

(NB Temperature profile developing in a sample over time is correlated to the degree of thermal damage. Each sample was observed under an applied constant heat flux at an average temperature of 600 degC for 1800 seconds/30 mins).

(1) Panel + single layer of 12mm MgO board:

Observed Thermal Damage - Low

(Comparative Temperature - 292 ^, degC

(2) Panel + single layer of 15mm FireLine board

Observed Thermal Damage - Low

(Comparative Temperature - 265 ^, degC)

(3) Panel + double layer of 15mm FireLine board

Observed Thermal Damage - Low

(Comparative Temperature - 147 ^, degC)

(4) Panel Alone

Observed Thermal Damage - High*

(Comparative Temperature - 539 ^, degC)

*NB Structural integrity of the Panel still intact after 30 minutes.

(1) Panel + single layer of 12mm MgO board:

Observed Thermal Damage - Low

(Comparative Temperature - 292 ^, degC

(2) Panel + single layer of 15mm FireLine board

Observed Thermal Damage - Low

(Comparative Temperature - 265 ^, degC)

(3) Panel + double layer of 15mm FireLine board

Observed Thermal Damage - Low

(Comparative Temperature - 147 ^, degC)

(4) Panel Alone

Observed Thermal Damage - High*

(Comparative Temperature - 539 ^, degC)

*NB Structural integrity of the Panel still intact after 30 minutes.

Mechanical Strength (Loading)

Axial Loads: ISO 22452

2400mm Panel - 174kN

Eccentric Loads: ISO 22452

2400mm Panel - 126kN

Racking: BS EN 594:2011 & ISO 22452

2400 Panel – 17.78kN (0kN Load)

2400 Panel – 26.77kN (25kN Load)

2400mm Panel - 174kN

Eccentric Loads: ISO 22452

2400mm Panel - 126kN

Racking: BS EN 594:2011 & ISO 22452

2400 Panel – 17.78kN (0kN Load)

2400 Panel – 26.77kN (25kN Load)

Condensation

Condensation Risk assessed in accordance with BS 5250:2002

Walls & Roofs - Minimal

Vapour Diffusion - Polyurethane +µ23

Interstitial Condensation – When walls and roof properly constructed – None (NB No requirement for vapour barrier)

Econic™ 9mm MgO Facing Board - Low Vapour Resistance 1:2Mns/g

Walls & Roofs - Minimal

Vapour Diffusion - Polyurethane +µ23

Interstitial Condensation – When walls and roof properly constructed – None (NB No requirement for vapour barrier)

Econic™ 9mm MgO Facing Board - Low Vapour Resistance 1:2Mns/g