The Panablok Structural Building System

Simple, Strong, Speedy, Safe & Sustainable.

As soon as Panablok panels are delivered to site, installation can begin. The Structural Building System is simple and easy to install, and panel erection requires rudimentary building skills. On the job training (when required) is part of the Panablok package, ensuring that developers and builders can quickly adapt to the new materials.

In a nutshell, panels are fixed into a floor (base) channel, which is connected to a suspended ground or intermediate floor. The panels are capped with a similar (head) channel, which provides the bearing for the upper floors, and the panels are “camlocked” together to form an airtight connection. Wall openings for windows and doors are easily accommodated and can be of any size and position, using bespoke lintels which are sized according to engineered structural strength requirements. Panablok floor and roof sections are fitted as soon as the walls are complete, and Panablok walls, floors and roofs are immediately loadbearing. The end result is a versatile, cost effective and extremely strong structure able to self-support up to six storeys without a frame.

The panels are ideal for new, stand-alone construction projects, or they can be integrated into almost any design plan as a like-for-like replacement for costlier and less efficient construction products. Traditional timber, steel and concrete floors or roofs fit directly to the panels, which also readily accommodate a huge variety of linings, claddings, renders and finishes.

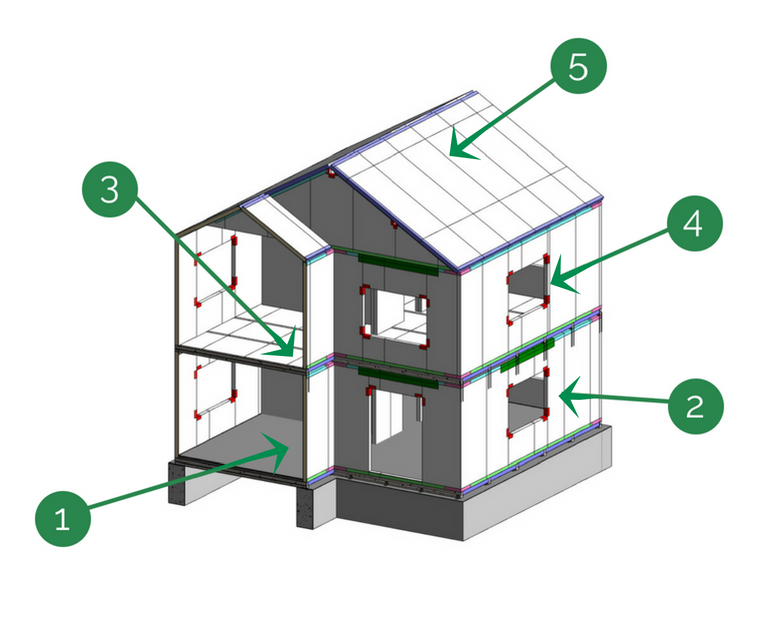

The Panablok Structural Building System can be broken down into five basic stages:

Our Structural Envelope Building System typically includes:

Insulated Structural Ground Floor

Ground Floor External, Internal and Party Walls

Structural First, Second, Third Floors etc.

External, Internal and Party Walls for each Intermediate Floor

Structural Ceiling*

Structural Roof*